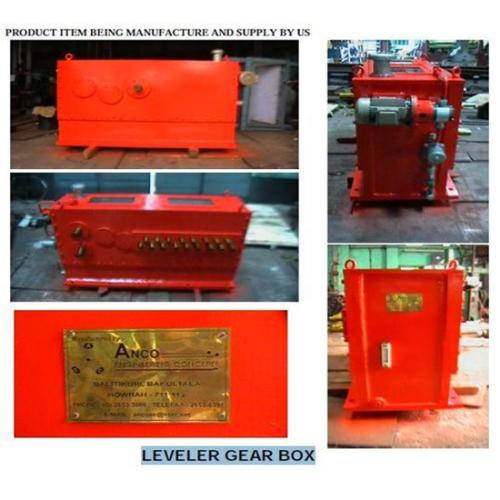

Leveler Gear Box

When levelling strips – especially on pre-levellers – very high stresses develop at the first roll shaft as the strip enters the machine, which are then distributed successively to the other roll shafts. In the case of levelling machines for panels or reversing lines the direction of load alternates, which makes extra demands on the gear system.

On the basis of in-depth knowledge of moments and loads occurring during straightening. Here the design details depend on actual requirements as regards number of output shafts, axle spacing, torques and the loads to be anticipated in production. Torque is distributed to anything up to 17 output shafts by means of a sophisticated distribution system.

Reduction gear stages are either integrated in the same housing as the distribution system or fitted as separate shaft-mounted units. This has the advantage that the system can be adapted to various straightening speeds without any need to alter the design of the levelling machine.